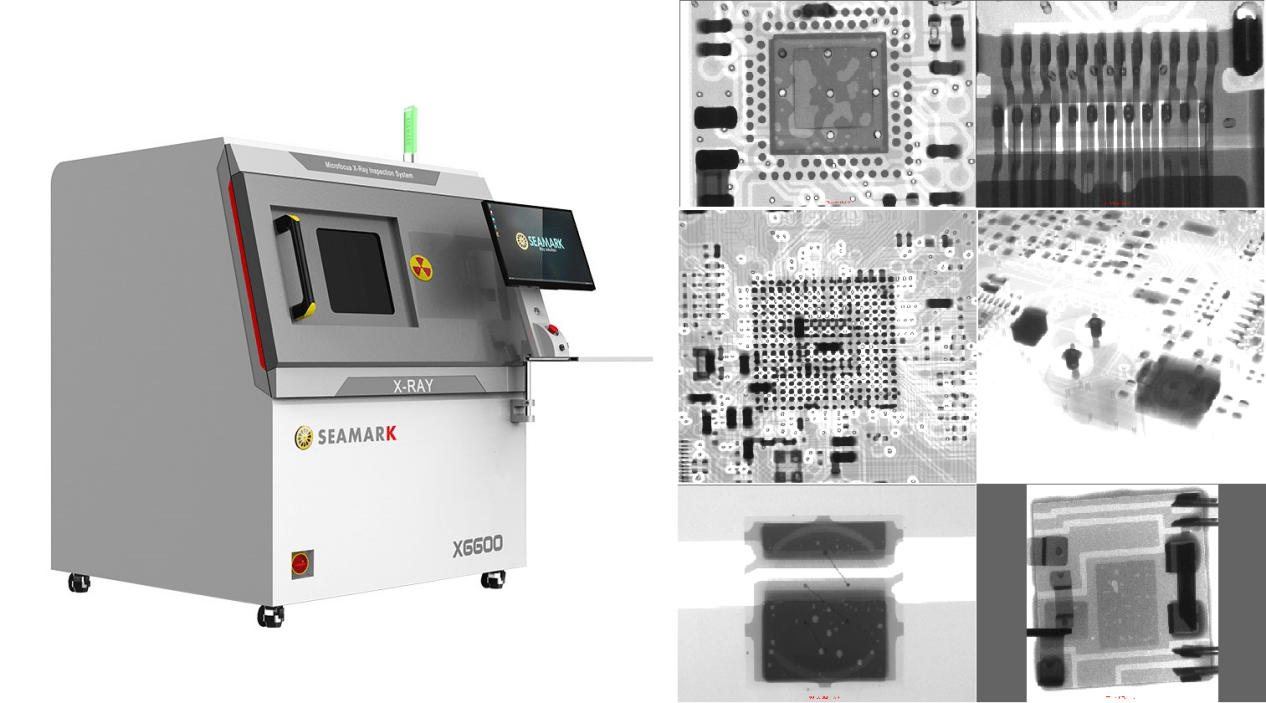

X-Ray multilayer circuit boards are suitable for multilayer circuit boards (PCB), circuit board assembly (PCBA), lithium batteries, semiconductor packaging, automotive

industry, etc. Observe and measure the position of the internal objects after packaging, find problems, determine whether they are qualified, and observe the internal

conditions.

X-Ray inspection of electronic components SMTBGA, CSP, Flip-Chip, IC electronic equipment internal penetration detection of semiconductor components, connectors,

wires, photovoltaic components, batteries, ceramic products, etc.

X-Ray non-destructive testing is used for auto parts, aluminum castings, hardware products, tire wheels, pressure vessels, refractories, boiler pipes, aviation parts and other

non-destructive testing. Online, offline and non-corrective customization;

IC semiconductor X-Ray inspection IC chips, BGA, IGBT, LED, WAFER, can be connected to internal quality inspection, online testing, intelligent judgment and sorting and

other electronic components MES system;

Lithium battery X-Ray aluminum shell power laminated battery, flexible packaging battery, cylindrical battery, lithium battery. Detect the internal defects of the battery and

analyze effectively, detect the positive and negative structure of the battery;

Aluminum alloy die-casting X-Ray aluminum alloy die-casting and turbine industry automatic identification, metal components, castings, precision components internal

testing, etc.

Automatic online X-Ray point machine is through the X-ray imaging principle to obtain image information, for the point machine, SMT production materials,

non-destructive testing, the introduction of artificial intelligence, deep learning image algorithm, no learning, automatic fast calculation of the actual number of materials,

the number of materials according to classification statistics, can print barcode paper or directly submit to the database management, Greatly improve work efficiency.